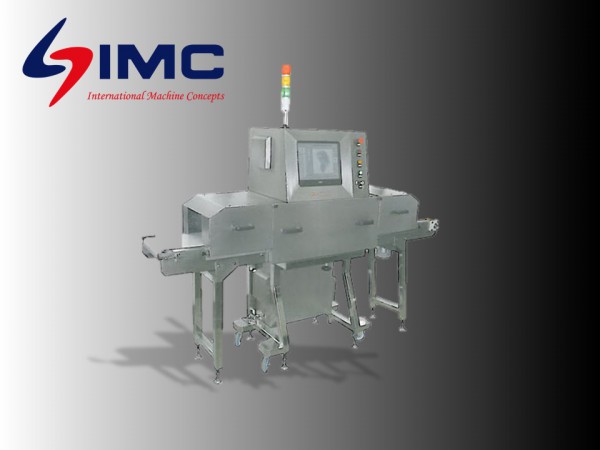

IMCXR-ZF X Ray Inspection System

Product Description

The technical parameter above namely is the result of sensitivity by inspecting only the test sample on the belt. The sensitivity would be affected according to the products being inspected and working condition.

The metal detector will have a sensitivity to a pre-programmed metal, and by test inspection of a sample on a belt. The sensitivity of the detector to the metal will then set the alarm off.

Detection Instructions

- Detection Method

The X-ray will irradiate the product to be detected and receive a transmission image, by using the image processing technology the machine will alert the operator to any foreign bodies in the image. - Detection Range

This detector can also detect metal through plastic packaging, aluminum packaging, glass, cans, metallic cans, bulk material etc. - Foreign Bodies’ Range

The machine can detect metal through high-density materials including metal and non-metal (stainless steel, ferrous, ceramic, stone, bone, hard plastic, hard ceramic, etc). The exact information can be given based on the products to be detected.

Advantages

- Full-range Inspection

A full-range inspection of foreign bodies including metal, non-metal; The detector can detect metal through metallic packages, non-metal packages, cans, etc. - High Sensitivity

The detector can reach sensitivity as follows: SUS304 ball 0.3*0.3*0.3mm

SUS wire0.2*2mm Glass Ball1.0 mm Ceramic 1.0 mm - Easy Use

Full-colour TFT 15" Touch Screen, Self-teach function, no need for manual settings: making the machine easy to operate. Auto-saving of the product image, making it easier to analysis and keep track of the image later. - Auto-shielding Function

According to the detection requirements, the machine can shield the low sensitivity area and improve the sensitivity as a whole. For example, it can shield aluminum parts of an object but detect the other metals in the same object. Therefore the aluminum parts won’t be regarded as foreign bodies and at the same time the sensitivity will still be high. - Highly adaptive to Environment

The machine is equipped with an industrial air-cooler and is therefore uninfluenced by the external environment and humidity. - Safety Protection

X-ray leakage is less than 1microsievert per hour; this meets the American FDA standard, European’s CE standard. Both the software and hardware are equipped with complete safety protection, which constantly inspects the state of the machine and stops any leakage caused by misuse of the machine. For example, if the operator opens the door of machine, the X-ray irradiation is stopped immediately. - Quality Guarantee

All the main parts such as the X-ray tube, X-ray detector, motor , inverter, etc are imported from world-famous leading brands to ensure the service life of the machine.

|

Model |

IMCXR-ZF |

|

|

X-ray tube |

MAX. 80kV, 320W |

|

|

Conveyor Parameter |

Speed |

5-40m/min |

|

Width |

600mm |

|

|

Max Height |

300mm |

|

|

Max Load |

30kg |

|

|

Best Inspection Ability |

0.4mm(SUS304 ball) 0.2*2mm(SUS304 wire) 1.0mm(glass) 1.0mm(ceramic) |

|

|

Screen |

Full-color TFT 15" Touch Screen |

|

|

O/S |

Windows XP Professional |

|

|

Connectivity |

LAN port, USB port |

|

|

Product Storage |

Max. Storage of the product parameter can reach 1000 kinds |

|

|

Product Management |

Complete product log |

|

|

Equipment Management |

MTBF, MTTR, Error logs, error analysis |

|

|

Parameter Adjustment |

Auto learning/Manual setting |

|

|

Image Management |

Auto image save/print/analyses |

|

|

Power Supply |

220V, AC, 50/60Hz |

|

|

Body Material |

SUS304 |

|

|

Purification |

Easy to wash |

|

|

Cooling method |

Air conditioned cooling |

|

|

Operation Temperature |

0-40°C |

|

|

Operation Humidity |

30-90% |

|

|

X-ray Emissions |

< 1 microsievert per hour |

|

|

X-ray Protection |

Removable Protective Curtain |

|

Next/Previous Machines